Container systems

Container systemsand container trade from Schunk Mobilraum

We offer you all-round services

For innovative and fast space solutions

From space analysis, planning and organization, transport and packaging, turnkey assembly on site to services, we realize everything that modern container construction has to offer at a high level.

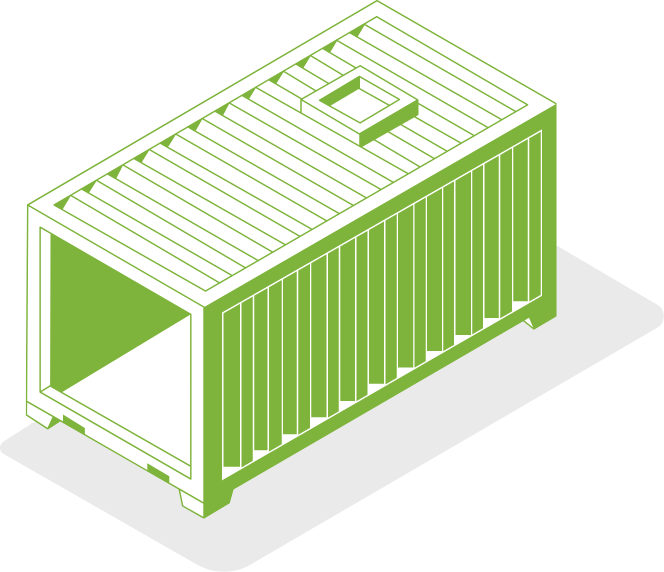

As a single element, in a compound up to a large-scale facility in camp dimension, the mobile room systems are suitable for almost every field of application.

Based on ISO standard containers, we create turnkey facilities that meet all current requirements and regulations.

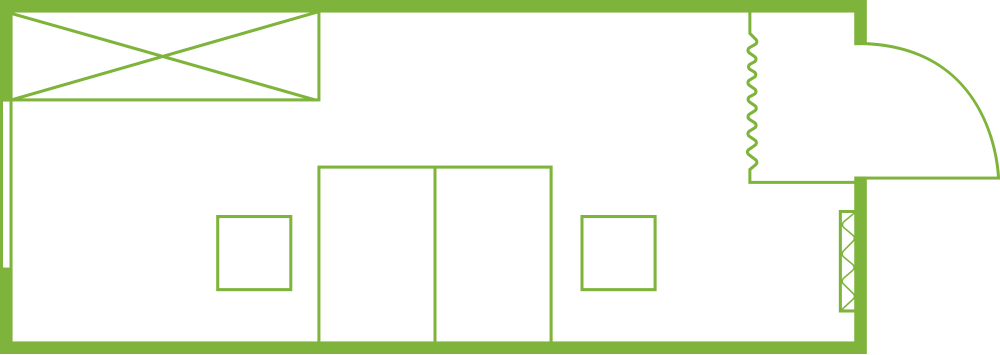

Standard dimensions

Lengths: 6,058 mm

Widths: 2,438 mm or 2,990 mm

Clear heights: 2,300 mm or 2,500 mm

Other clear heights are possible within the framework of “special construction”.

External heights: 2,600 mm or 2,800 mm

Structure

This is how our containers are constructed

Our standard solutions are due to their construction from

ISO standard containers, our standard solutions are an economical alternative to other

construction systems. They can be realized at short notice and have a high mobility.

high mobility.

You determine the position of the windows, doors, etc. – their number, how many elements you want to connect. And whether you want only a first floor or also 1st and 2nd floor.

Welded steel structure made of hollow and rolled sections according to DIN EN 1090 protective priming with 2-component primer 20-30 μm, painting 80-120 μm with polyacrylate-based paint, in RAL tone according to the customer’s choice; corners are equipped with fastening fittings (corner castings), housing made of 5 mm steel sheet. The standard version of this frame is 2-fold stackable, according to verifiable statics, which means that it is possible to design a plant on 3 levels, ground floor/1st and 2nd floor, with this basic frame.

0.7 mm galvanized profiled sheet as blind floor. The sheets are riveted to the floor cross members in accordance with the statics. At least 80 mm mineral wool insulation, color Prefizol, fire behavior according to DIN 4102, k = 0.426 W/m²K or, if required, according to EnEV , 0.2 mm polyethylene film as vapor barrier, 19 mm (min.) chipboard V100, protection class F0 (formaldehyde-free), make Spanatex, according to DIN 68 763, screwed to sectional steel beams (floor cross beams according to statics). 1.5 mm PVC floor covering, laid in strips, glued over the entire surface, butt joints homogeneously welded, wall/floor joints sealed with permanent elastic. The wall finish is formed by a hard core skirting board.

Live load of the floor: 2500 N/m².

The traffic load can be increased at the customer’s request. Design and prices on request.

0.75 mm galvanized profiled sheet, seepage depth 40 mm, ventilated, bearing laid and fastened from specially folded roof profiles according to statics, welded flush with the frame construction. At least 80 mm ineral wool insulation, color. Prefizol, fire behavior according to DIN 4102, k = 0.465 W/m²K or if required according to EnEV, 0.2 mm polyethylene film as vapor barrier. 10 mm chipboard coated on both sides with melamine resin, protection class F0 (formaldehyde-free), manufactured by Spanatex, according to DIN 68 765, white decor, riveted to sectional steel girders (roof cross girders according to statics) with ALU blind rivets. The rivet heads are covered with plastic caps in matching colors. All butt and corner joints are provided with special plastic strips The roof is designed for a roof load of 1250 N/m².

Roof drainage is provided by four DN 60 PVC downpipes housed in the corner posts, which are attached to a pipe socket inserted in the upper container boxes. On request and for an extra charge, we can supply the container with a monopitch/cold roof. This roof construction is made of steel profiles, the roof covering is made of galvanized trapezoidal profile sheets. The roof drainage is provided by pre-hung galvanized gutters and two downpipes mounted on the container corners. The roof drainage pipe is mounted behind a 6-fold folded parapet, consisting of galvanized steel sheet, approx. 1 mm thick, screwed to the roof frame with brackets. The parapet is painted with a UV and weather resistant 2-component paint. The fascia height is 500 mm.

0.55 mm galvanized profiled sheet, 7 mm bead depth, primed and painted in RAL color as requested by the customer and riveted to galvanized U-section steel truss structure. The dimensioning of the U-profiles depends on the thickness of the mineral wool insulation to be inserted into the truss construction. At least 60 mm mineral wool insulation, color. Prefizol, fire behavior according to DIN 4102, k = 0.590 W/m²K or, if required, according to EnEV. 0.2 mm polyethylene film as vapor barrier

10 mm chipboard coated on both sides with melamine resin, protection class FO (formaldehyde-free), manufactured by Spanatex, DIN 68 765, decor: white or light oak, riveted with ALU blind rivets to the galvanized U-profile steel framework construction described at the beginning. The rivet heads are covered with plastic caps in matching colors. All butt and corner joints are provided with special plastic strips. The outer wall is provided with forced ventilation at the end faces, executed with external gill plate as well as internal plastic grille incl. insect screen. A PVC pipe DN 100 mm is mounted between the outer sheet and the grille to protect the insulation.

Individual adjustments possible at extra cost:

- a different facade design: trapezoidal sheet, smooth sheet, wood cement board with structural paint, plaster, etc.

- a differentiated interior design: with melamine resin panels coated on both sides in various decors, structural paint, plating of wall and floor surfaces, etc.

- an upscale equipment in the field of sanitary equipment, electrical equipment (lighting, etc.) and furniture, etc.

Building application?

We will do it for you

- Proof of stability / the statics

- Foundation plan

- Thermal insulation certificate and energy balance

- Floor plan / elevation and sectional drawings

- Presentation of the welding certificate according to DIN EN 1090

Do you have questions about container systems?

Please feel free to arrange a non-binding consultation appointment!